PCBA Processing OverviewShenzhen Geyaxin Electronics Co., Ltd. specializes in industrial PCBA design and production. The products cover industrial automation equipment, industrial production equipment control boards, industrial robots, automotive electronic control boards, industrial printing and coding equipment, servo control boards, and CNC machine tools. Provide one-stop service for project development, PCB board, component purchasing, SMT production, maintenance and debugging, quality assurance and maintenance.

Has a professional team, electronic product development, SCM application design, in one of the high-tech companies. Senior hardware and software development can use rich technical resources and rich product project management experience to help you in the whole process of product design, product production, project promotion, and project support, and work with you to complete every aspect of the project. In addition to all program designs, we fully considered the product's scalability and scalability to solve your worries. The powerful technical force thus enables us to recommend to our customers the best cost-effective and most reliable solution in the shortest possible time.

The quality of electronic components procurement is stable, the channels are regular, and the procurement personnel are familiar with electronic raw materials. They have a certain understanding of the performance of electronic components. Especially good at partial out-of-poor (such as military and industrial products), stop production, broken files, shortage of IC and imports of industrial profile cold connector purchase.

All PCBA products produced by the company are shipped in full inspection, ensuring that customers can directly assemble and use them. The quality assurance system is perfect to solve the customer's worry about sales. Under the premise of guaranteeing quality, we provide you with superb speed.

PCBA processing capacity

With a professional team of technical engineers and rich experience in PCBA processing, the company strictly checks and analyzes the customer BOM list and related technical documents. It strictly checks the process flow and conducts rigorous testing for each set of products to provide a full range of services. Service materials.

PCBA processingPCBA processing business process

1. The customer proposes his own PCBA processing requirements and provides the data files required for processing.

2. The company analyzes customer requirements and data files.

3. The company confirms the processing plan according to the customer's request and quotes it to the customer.

4. Purchasing the required materials in accordance with the requirements of the customers in accordance with the processing requirements.

5. Production prototypes, testing, feedback to customers.

6. Arrange mass production.

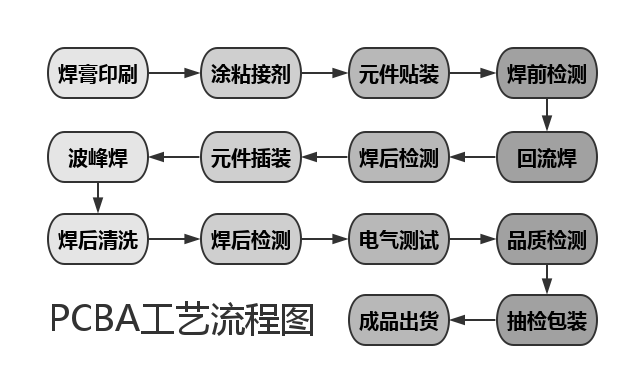

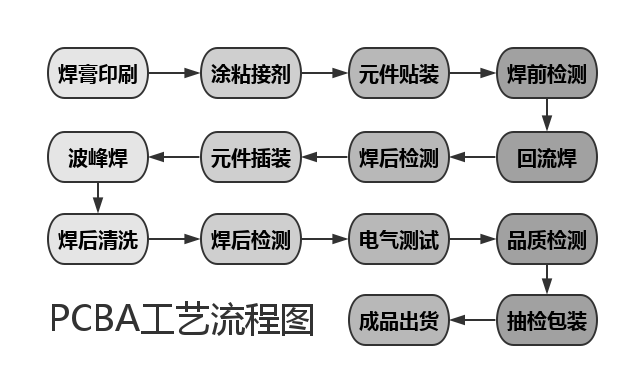

PCBA processing process

Printed solder paste

The squeegee pushes the solder paste along the surface of the stencil. When the solder paste reaches an open area of the stencil, the downward pressure exerted by the squeegee forces the solder paste through the stencil opening area onto the PCB board.

2. Apply adhesive

Double-sided assembly of the PCB board To prevent the bottom surface mounting components or the double-sided reflow soldering during wave soldering, the bottom large integrated circuit device is melted and dropped, and the adhesive is required to stick the components. In addition, in order to prevent the positional movement of the heavier components when the PCB is transported, it is also necessary to stick it with an adhesive.

3. Component placement

The process is to use an automated placement machine to pick up surface mount components from the feeder and accurately place them on the printed PCB board.

4. Pre-weld and post-weld inspection

Before components pass through reflow soldering, it is necessary to carefully check whether the component is mounted properly and the position is not offset. After the welding is completed, the solder joints and other quality defects need to be inspected before the assembly enters the next process step.

5. Reflow welding will

After the component is placed on the solder, the solder on the pad is melted using a thermal-convection flow soldering process to form the mechanical and electrical interconnection between the component leads and the pad.

6. Component insertion

For surface mounted components such as through-hole insertion components and certain machines, such as some cartridge electrolytic capacitors, connectors, push button switches, and metal end electrode elements (MELF), for manual insertion or use Automatic insertion equipment for component insertion.

7. Wave soldering

Wave soldering is mainly used to weld through-hole insertion components. When the PCB passes over the crest, the solder wets the leads that have leaked from the bottom of the PCB, and the solder is attracted into the plated sockets, forming a tight interconnection of components and pads.

8. Cleaning

Optional process. When the solder paste contains organic components such as rosin and lipids, the residues formed after the solder paste is combined with the water in the atmosphere have strong chemical corrosiveness, and remaining on the PCB board will hinder the reliability of the circuit connection. Therefore, these chemicals must be thoroughly washed away.

9. Maintenance

This is an off-line process that aims to economically repair defective solder joints or replace defective components. Maintenance can basically be divided into three kinds of repair welding, heavy industry and repair.

10. Electrical testing

Electrical testing mainly includes on-line testing and functional testing. On-line testing checks the connection of each individual component and test circuit is good. Functional testing determines whether the entire circuit can achieve a predetermined function by simulating the working environment of the circuit.

11. Quality Management

Quality management includes quality control within the production line and product quality assurance before delivery to customers. It is mainly to check the process control status of defective products and feedback products and ensure the quality indicators of the products to meet the requirements of customers.

12. Packaging and sampling inspection

Finally, the components are packaged and sampled after packaging to ensure that the products to be delivered to customers are of high quality.

PCBA processing caseThe core business of the company is mainly PCBA small and medium-volume production of industrial control board types. Its products cover industrial automation equipment, industrial production equipment control panels, industrial robots, automotive electronic control boards, industrial printing and coding equipment, servo control boards, and CNC machine tools. Motherboard, smart furniture board, 3D printer control board and other fields.

After-sale warranty

Our company provides PCBA processing through-train service, which can fully entrust your company with the requirements of your electronic solution. Our company will complete the quality and quantity efficiently and be responsible for the follow-up product installation, commissioning, use and maintenance.